Specialized Technology Platforms

We understand that there are many membrane platforms to consider when selecting one for your separations. Our position is technology agnostic and we will find one that will best fit your needs. Our staff has a diverse background in membrane technology and can offer a number of platforms for industrial separations . These include:

Ceramic membranes – Ceramic membranes a wide range of separations capabilities in thermal and chemical conditions where for separation applications where polymeric membranes cannot. An existing partnership with ceramic membrane producer Fraunhofer IKTS and Rauschert give us access to a variety of ceramic membranes for many different separations processes.

Polymeric Membranes – Polymeric membranes have applications across liquid and gas separations. They are available in numerous geometries (flat sheet, hollow fiber) at a competitive price point. The team has in-depth experience in-depth experience in reverse osmosis, forward osmosis, nanofiltration (aqueous and non-aqueous), membrane distillation, and gas separations.

Mixed Matrix Membranes – The combination of polymeric and inorganic materials may enable unique separation properties in membranes. We work with mixed matrix membranes and have developed unique approaches to fabricate them for liquid, vapor, and gas separations applications.

Air Filtration/PPE Materials – We have in-house capabilities to test materials that can be used in air filtration or for personal masks and respirators. While we can provide a myriad of testing services (including a pre-certification for NIOSH testing that is required for n95 designation), we can also produce filtration media using processes such as electrospinning and casting. We can farm out or purchase other materials for filter material development.

Ion Exchange/Adsorption – We can work with commercial off-the-shelf absorbers or ion exchange resins for specific separations that may be needed as part of a hybrid separation system.

Other Separations Needs – We have a strong network of collaborators here and abroad who can provide information that may be outside of our core expertise. If we cannot do what you need, we can find someone who can.

Fee for Service Work and Applied R&D

CCAST executes a wide range of fee for service work and applied R&D on behalf of the client. Being a not-for-profit organization as well as part of a public institution, this allows us to best serve the interest of the client while maintaining extremely reasonable costs. Such work includes but is not limited to:

- Testing for air filtration, mask material and PPE for particle filtration (before and after disinfection, including NIOSH standard testing for n95 and n99

- Applications testing utilizing lab bench scale, prototype, pilot scale testing of membrane and/or separations process with a variety of feed streams

- Testing for air filtration and mask material for particle filtration (including NIOSH standard testing for n95 and n99

- Membrane characterization, innovation, development, validation and synthesis (performance, longevity) for any separations need

- Design, fabrication and testing of customized bench or pilot scale separations prototype systems

- Technology evaluation / validation for certain applications

- Technology comparison/benchmarking of commercial options for tailored separations needs

- Development of standard operating procedures for customized systems and membrane elements

- Designing and trialling a solution for your separation challenges

- Analysis of mass transfer processes and membrane separation mechanisms

Mask, Respirator & Filter Testing

The Connecticut Center for Applied Separations Technologies (CCAST) is offering mask, respirator, and filter testing services in Storrs Connecticut. These services can evaluate the performance of PPE as well as other filter media intended for air and gas filtration. More information on tests and costs can be found here.pdf.

Standardized Separation Equipment Testing

One (1) coupon and small element gas permeation (CCAST)

One (1) coupon and small element gas permeation (CCAST) One (1) flat sheet benchtop pervaporation

One (1) flat sheet benchtop pervaporation One (1) small element pervaporation

One (1) small element pervaporation One (1) element-scale FO / One (1) element scale RO

One (1) element-scale FO / One (1) element scale RO One (1) bench-scale UF/NF for tubular membranes

One (1) bench-scale UF/NF for tubular membranes One (1) filtration media test system for small coupons (non-NIOSH)

One (1) filtration media test system for small coupons (non-NIOSH) One (1) filtration media test system for small coupons (non-NIOSH)

One (1) filtration media test system for small coupons (non-NIOSH) One (1) Rauschert InnoMini

One (1) Rauschert InnoMini One (1) Vacuum MD System

One (1) Vacuum MD System

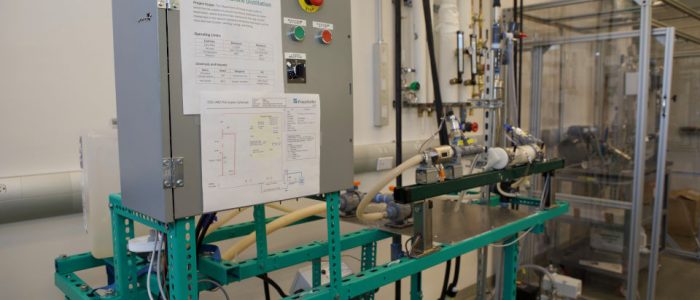

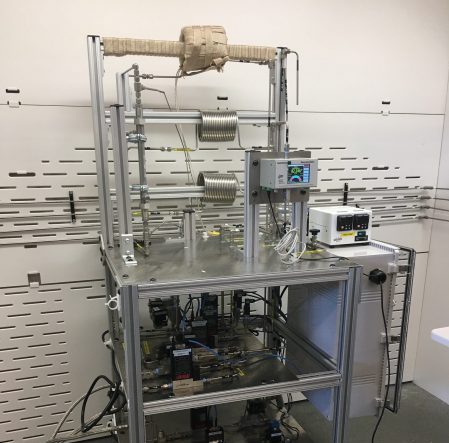

Our center has a wide variety of separation equipment for our clients testing needs. The equipment include:

- One (1) coupon and small element gas permeation

- One (1) flat sheet benchtop pervaporation

- one (1) small element pervaporation

- One (1) flat sheet and small element membrane distillation (Photo is coming!)

- Three (3) flat sheet forward osmosis (Photo is coming!)

- One (1) flat sheet pressure retarded osmosis (Photo is coming!)

- Twelve (12) benchtop flatsheet RO test cells (over 2 systems) (Photo is coming!)

- One (1) element-scale FO

- One (1) element scale RO

- One (1) bench-scale UF/NF for tubular membranes

- One (1) TSI automated mask testing system using a NIOSH standard (Photo is coming!)

- One (1) filtration media test system for small coupons (non-NIOSH)

- One (1) Pilot UF/NF

- One (1) Rauschert InnoMini

- One (1) Vacuum MD System

Additional LINK to Specifications, Applications & Operating Limits for certain equipment can be found here

- Forward Osmosis Reverse Osmosis Applications Sheet.pdf

- Forward Osmosis Reverse Osmosis Operating Limits.pdf

- Gas Permeation Applications Sheet.pdf

- Gas Permeation Applications Sheet Operating Limits.pdf

- Membrane Distillation Applications Sheet.pdf

- Membrane Distillation Operating Limits.pdf

- Pervaporation Applications Sheet.pdf

- Pervaporation Operating Limits.pdf

- Ultrafiltration Nanofiltration Applications Sheet.pdf

- Ultrafiltration Nanofiltration Operating Limits.pdf

- Ultrafiltration Nanofiltration Mini Solvent Operating Limits.pdf

- Ultrafiltration Nanofiltration Pilot Plant Operating Limits.pdf

Customized Separation Equipment Fabrication & Testing

For our clients who have very specialized separation requirements, our center has the in-house expertise and experience to design and fabricate customized test separation equipment. Services include:

- Design, build, and delivery to the customer for their use accompanied with training and instructions for standard operating procedures.

- Design, build, and operate a system in-house for testing services with customer.

Examples of some of our customized test units are:

- Filtration equipment for extreme pH solutions.

- Specific removal of substances based on customer requirements using membranes or ion exchange.

- Membrane test unit for harsh produced waters for operation under extreme conditions

- Air filtration testing unit to measure particle capture in air filters and mask materials

- Membrane-based dehumidification system

Analytical Resources

CCAST has access to the state-of-the-art research infrastructure at the University of Connecticut to perform a variety of analytical testing. Extensive materials characterization and liquids/gas analysis facilities are available for a fee via our fellow university centers like the Center for Environmental Sciences and Engineering, the Connecticut Center for Clean Energy Engineering, the Institute of Materials Science, and Innovation Partnership Building at UConn Tech Park.

Specific analytics of interest may include ion analysis (metal ions), organics analysis (e.g. PFAS, cannabis products, pharmaceuticals), and various water quality analyses

The range of analytical equipment available is vast and include but are not limited to:

- Perkin Elmer/DRC-e Inductively Coupled Plasma Mass Spectrometer (ICPMS) with a CETAC Laser Ablation unit

- Perkin Elmer Optima 7300DV Inductively Coupled Plasma Optical Emission Spectrometer (ICP/OES)

- Perkin Elmer FIMS Cold Vapor Atomic Absorption Spectrometer (CVAAS)

- Milestone DMA-80 Direct Mercury Analyzer

- Brooks Rand Model III Cold Vapor Atomic Fluorescence Spectrometer (CVAFS)

- Lachat QuikChem 8500 Flow Injection Ion Auto Analyzer,

- Shimadzu TOC-L Total Organic Carbon (TOC) Analyzer

- Perkin-Elmer 2400 Carbon, Hydrogen and Nitrogen (CHN) Analyzer,

- Dionex DX500 Ion Chromatograph,

- Waters Acquity Ultra Performance Liquid Chromatograph (UPLC) equipped with: Tandem Mass Spectrometer (MS/MS), Photodiode Array Detector (PDA), Evaporative Light Scattering Detector (ELSD) & Fluorescence Detector (FLR)

- Waters Quattro Micro Gas Chromatograph-Tandem Mass Spectrometer (GC-MS/MS)

- Agilent 6890 GC w/ Electron Capture Detector (GC/ECD)

- Hewlett Packard 5890 GC w/ Flame Ionization Detector (FID) .

- Perkin Elmer Series 200 High Performance Liquid Chromatograph (HPLC) equipped with: Photodiode Array Detector (PDA)

- Atomic force microscopy (AFM)

- Nuclear Magnetic Resonance Spectroscopy (NMR)

- ZSX Primus IV XRF Spectrometer

- Titan Themis

- Talos TEM

Specialized Consulting Services

CCAST strives to be your cost-effective solution provider for separations needs across the disciplines of water, solvent, vapor and gas. We are always ready for new separation challenges and are eager to learn about your separation needs. We pride ourselves in being technology agnostic, meaning we can objectively assess a technology for your needs or provide technical diligence on your new technology. We also keep in close contact with an extensive network of industry end users and understand the various sectors pain points. Should your separation challenge not fall within our expertise, we will gladly make introductions to others in our network.

Partnering on Federal and State Grants

Dr. McCutcheon is an experienced grant writer who has raised over $10M in funding from federal and industry sources during his career. He has extensive experience in grant writing and has served on the panels that review proposals for several government agencies.

CCAST has partnered with various SMES (Small Medium Enterprises) on their SBIR grants and are willing to explore any opportunity to seek federal and state funding on development, validation, and deployment of new separations technologies.

Dr. McCutcheon is also involved in the newly formed National Alliance for Water Innovation, a $100M hub on desalination technology funded by the U.S. Department of Energy. Projects funded in this hub require collaborations between industry and the research community.

Refereed Publications

Dr. Jeff McCutcheon, who leads CCAST, is an accomplished researcher who has published over 90 refereed publications, 3 book chapters, and several patents on membrane technology. Though publishing is not expected or required when working with us, our high caliber team are eager to explore publication opportunities if our clients seek it. To learn more about this, please contact us just for a consult.