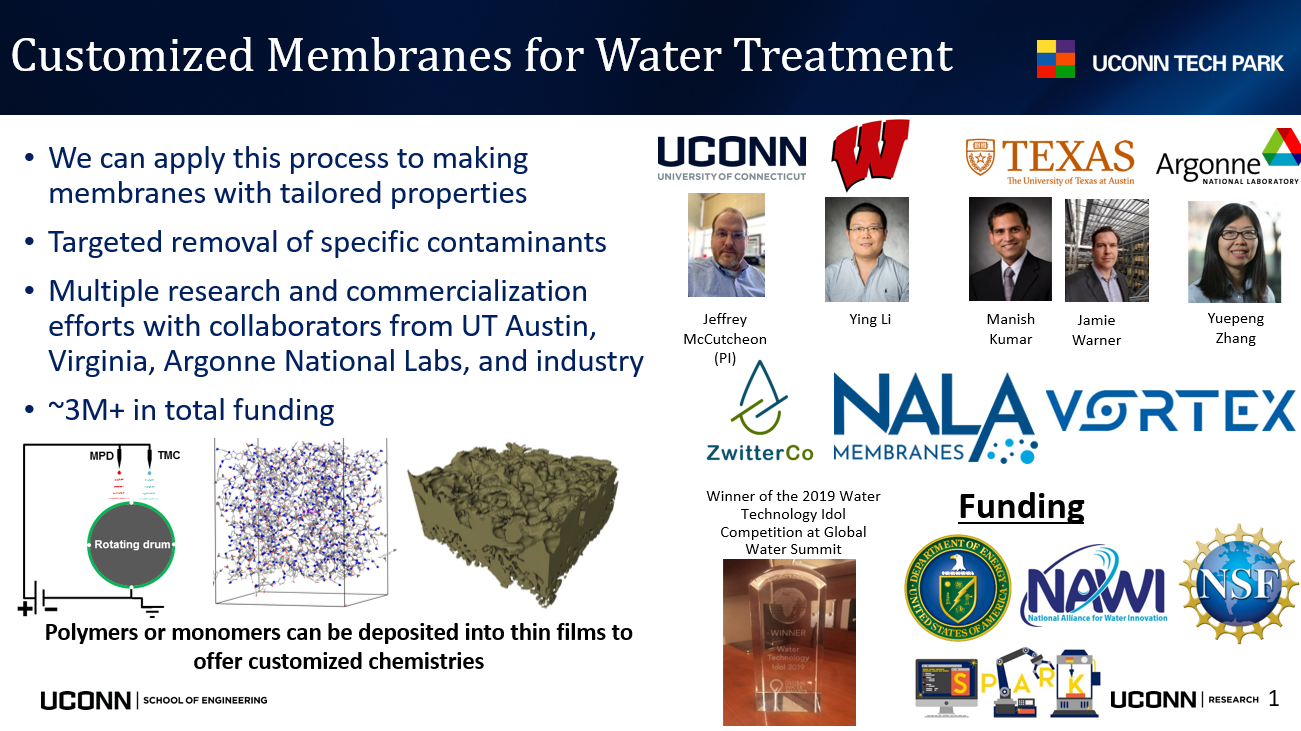

Customized Membranes for Water Treatment

The National Alliance for Water Innovation is supporting work on developing customized membranes for water treatment. The UConn process uses electrospray 3D printing to synthesize polyamide RO and NF membranes with targeted selectivities that support the development of new desalination technologies such as osmotically assisted reverse osmosis (OARO) and low salt rejection reverse osmosis (LSRRO). The project is supported by molecular dynamics approaches that help identify polyamide precursor chemistries that lead to membranes with desirable characteristics. Those MD techniques will be validated by transmission electron microscopy tomography that provide three-dimensional density mapping of our thin film membranes.

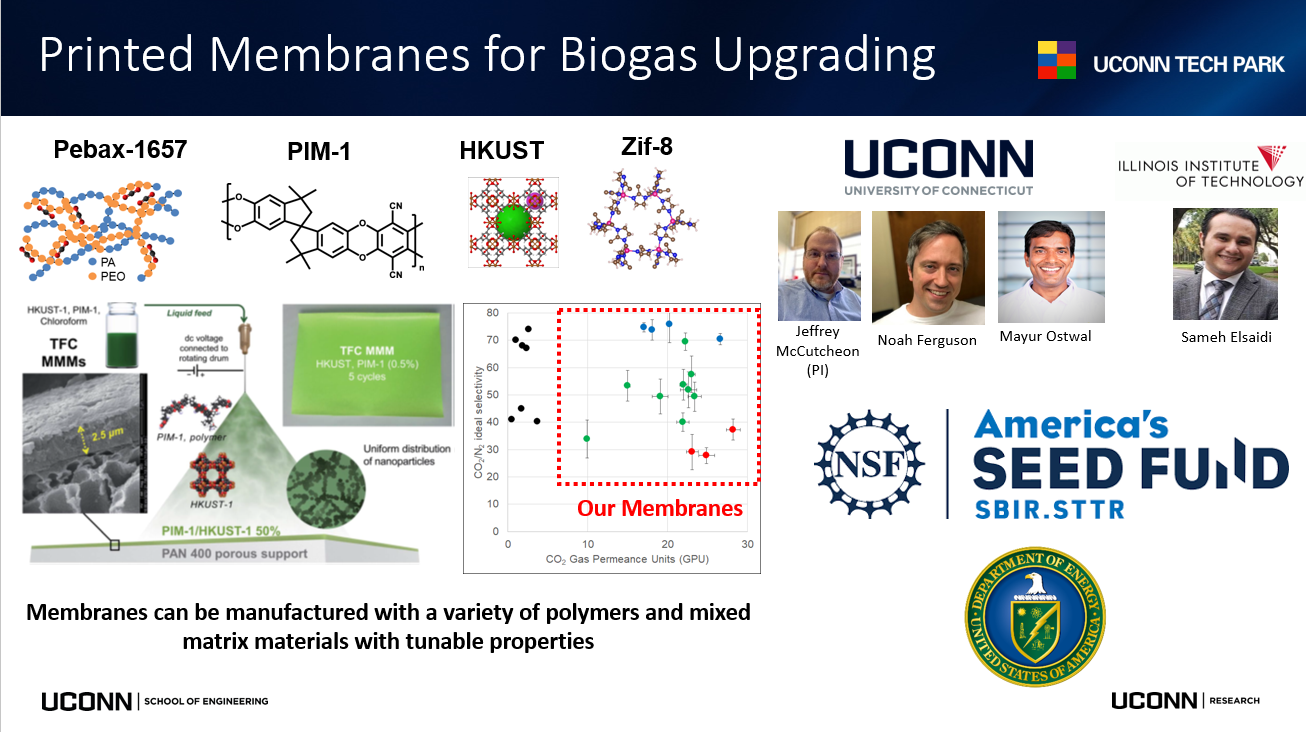

Printed membranes for gas separations

We are using additive manufacturing to support gas separations membranes development. With an initial application of biogas upgrading being considered, we are evaluating the printing of classical materials for gas separations membranes (e.g. PEBAX, polymers of intrinsic microporosity). We are also integrating nanomaterials into these membranes (i.e. mixed matrix membranes) using the same approach.

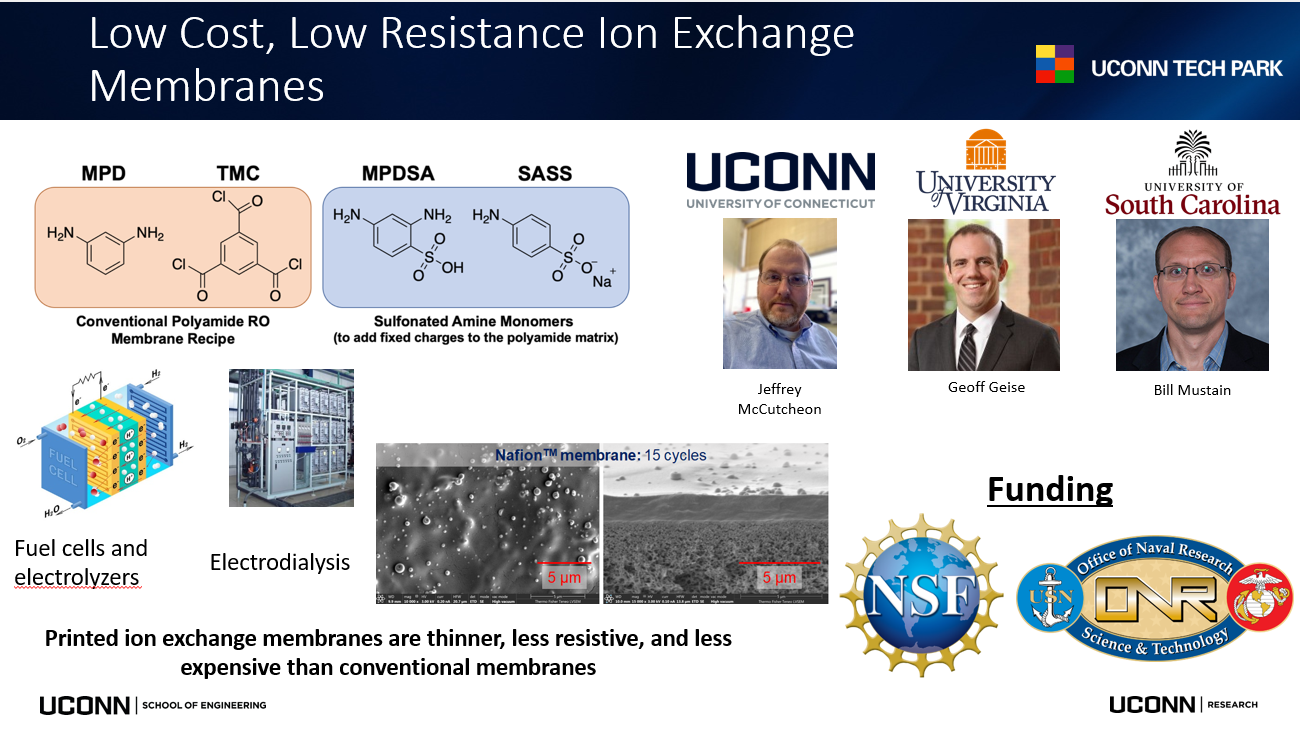

Low cost, low resistance ion exchange membranes

We are printing ion exchange membranes using both classical materials (Nafion®, Sustainion®) and newly synthesized polymers (sulfonated polyamide). Using electrospray 3D printing, we have successfully made defect free films that are little as 100 nm in thickness yet still offer ion selectivity. The result will be low resistance ion exchange membranes that will improve electrodialysis, electrolysis, fuel cells, and their sibling electrochemical technologies. We are actively exploring new material options as well as we examine the tradeoffs between metrics like ion resistance and gas permeability (for electrolyzers and fuel cells).

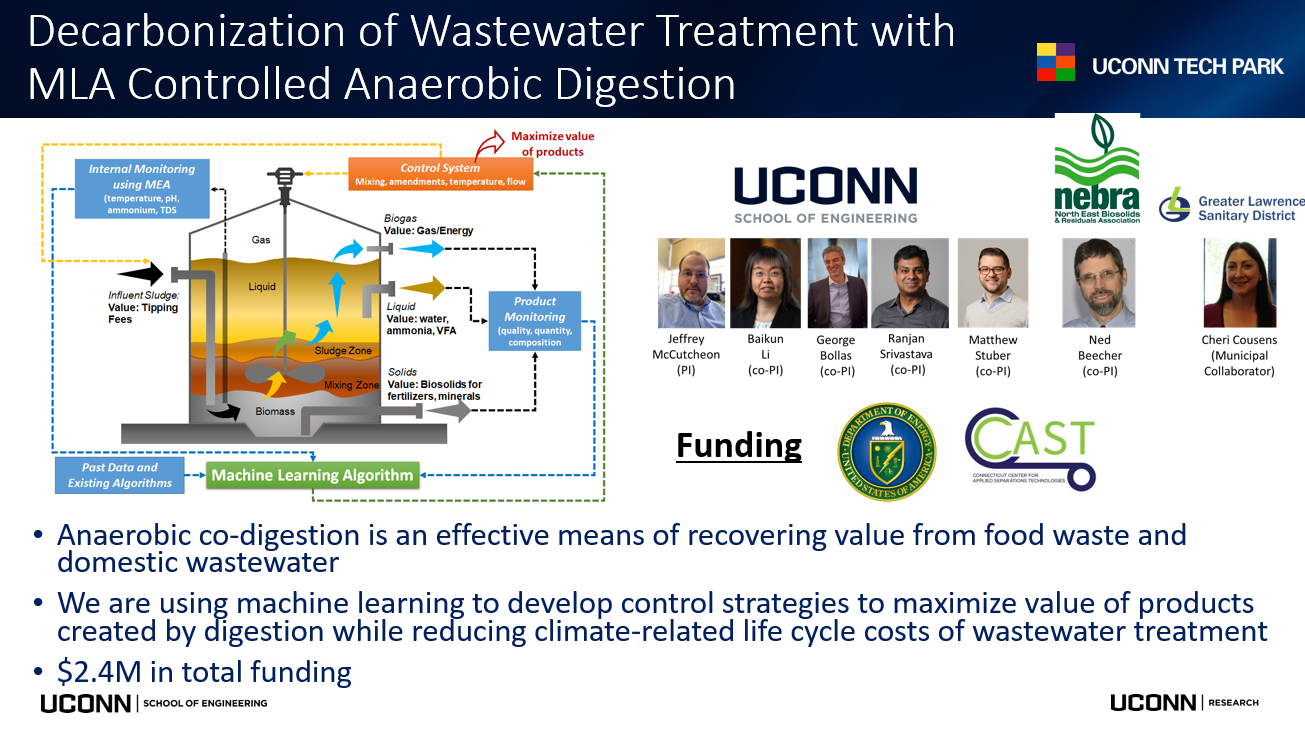

Decarbonizing Wastewater Treatment with MLA Controlled Anaerobic Digestion

Anaerobic digestion (AD) offers a means of converting organic residuals from wastewater treatment, agriculture, and food waste into carbon neutral energy. AD relies on the biological conversion of these wastes into biogas, which is a blend of methane, carbon dioxide, and other gases. These systems can be fickle, however, and require a deep understanding of their internal workings of a digester to maximize gas production (or other metric of performance). Our collaborative team is developing sensor technology to measure performance of digesters currently in use by our partner the Greater Lawrence Sanitation District (GLSD). These sensors will provide data to validate a digital twin of the GLSD digesters and ultimately to provide data to train a machine learning algorithm that will provide predictive control capability for these digesters.

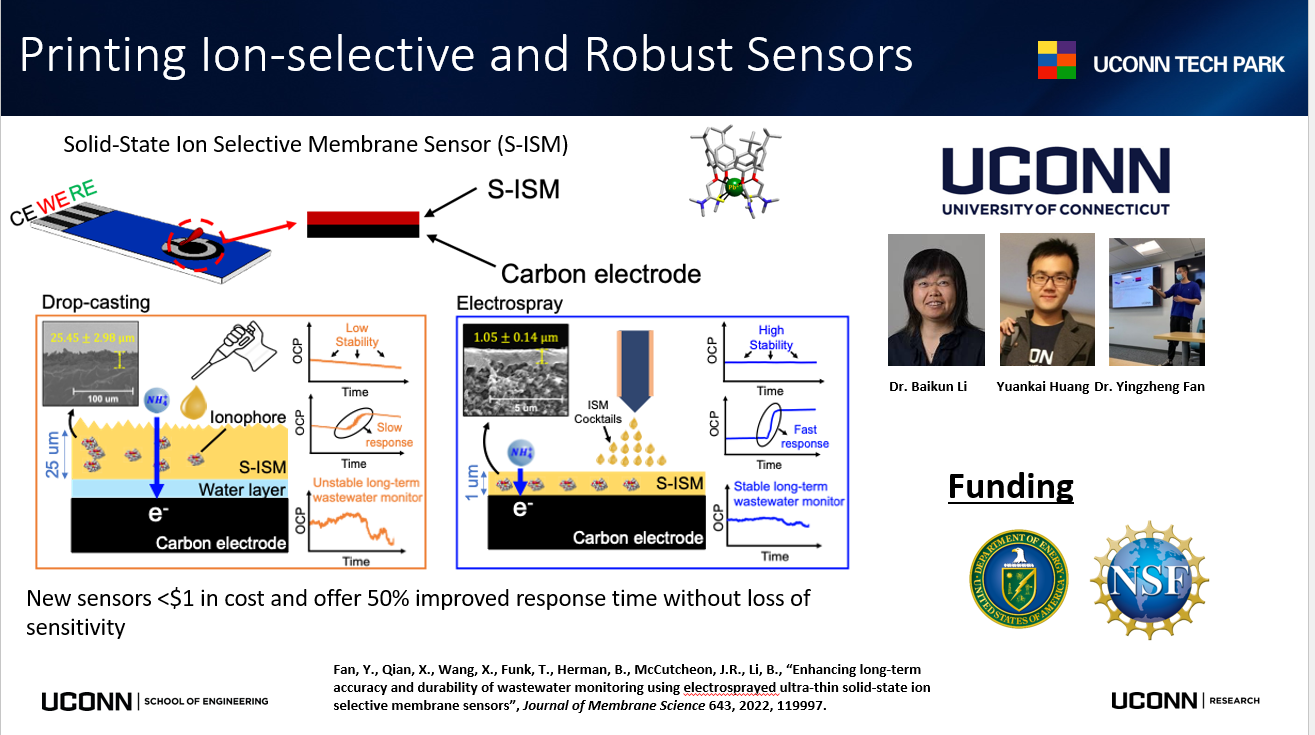

Printing Ion-Selective and Robust Sensors

We are printing ion selective membranes onto carbon electrodes to create sensors for ammonium, nitrate, and key metal contaminants in municipal, industrial, and mining wastewaters. These sensors can also be coated with hydrophilic coatings that are thin enough not to impact sensor response yet with pore sizes large enough so as not to impact selectivity. This project is a collaboration with Prof. Baikun Li in the Civil & Environmental Engineering Department at UConn.

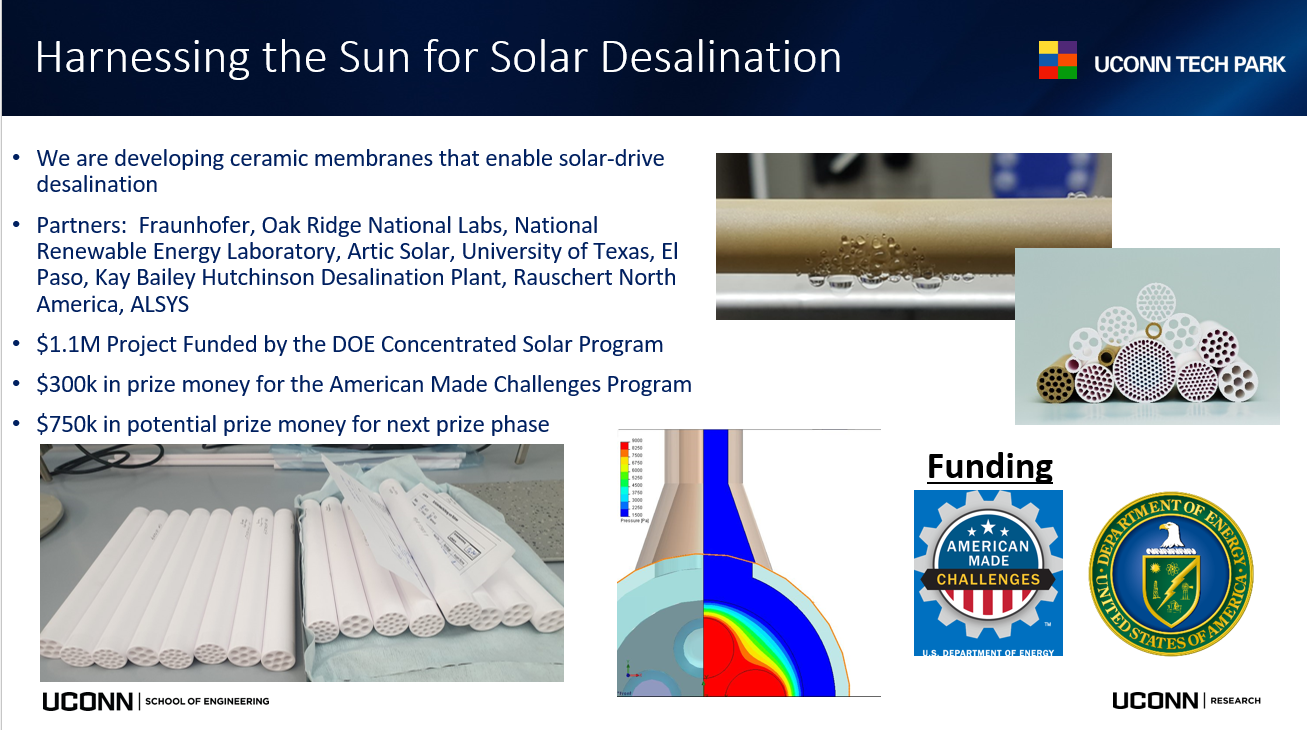

Harnessing the Sun for Solar Desalination

We are developing a hydrophobic ceramic membrane for vacuum membrane distillation. This membrane will enable higher temperature membrane distillation that can leverage solar thermal collection technology. The ceramic membrane also offers excellent resiliency to rigorous cleaning protocols that enable them to be used in very challenging environments (e.g. produced water, industrial wastewater). We have partnered with a number of collaborating entities, including the National Renewable Energy Laboratory, Oak Ridge National Laboratory, and Fraunhofer IKTS in Germany for these projects.

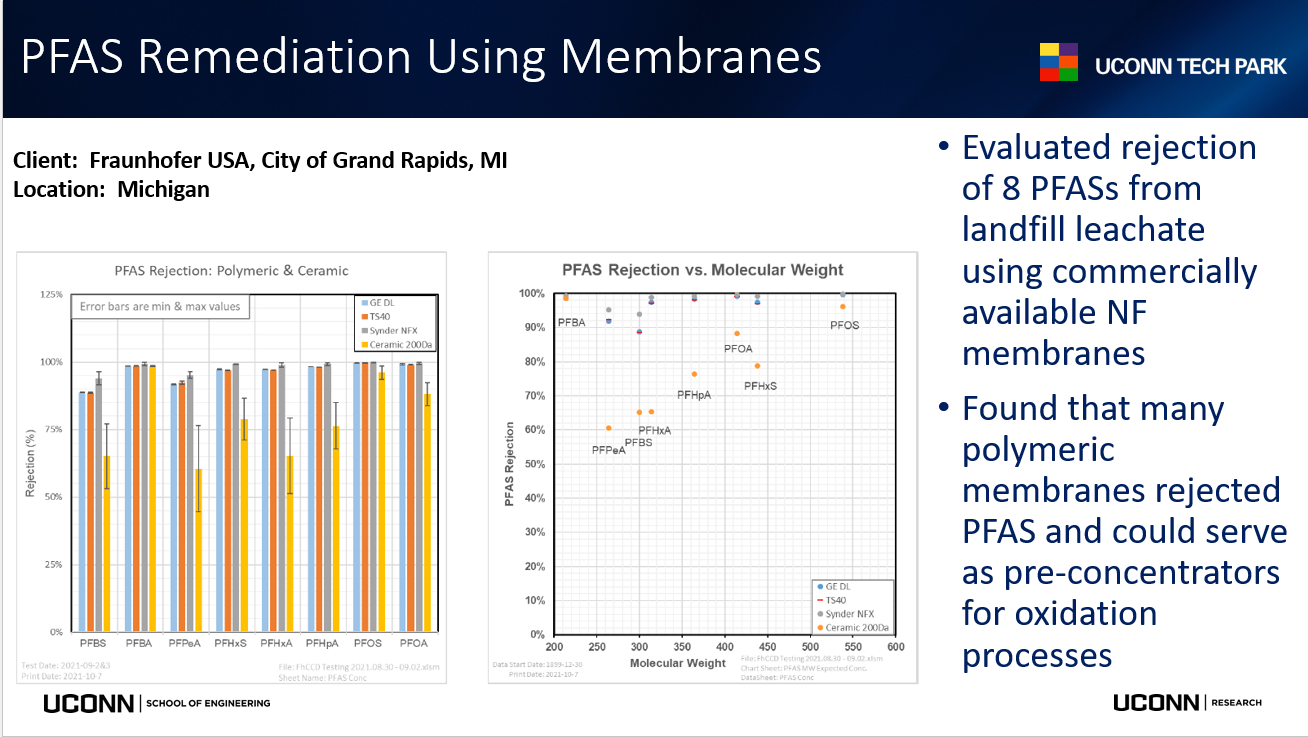

PFAS Remediation using Membranes

PFAS is a class of emerging contaminant of concern that is ubiquitous in our environment. Colloquially referred to as “forever chemicals”, PFAS is used in everything from coatings of pans and fabrics to fire fighting foams. These materials end up in the water supply and then accumulate in the human body where they are believed to have adverse health effects. PFAS can be destroyed in water, but the techniques used are expensive and energy intensive. Membranes can be used to concentrate PFAS molecules prior to the use of destruction techniques, thus reducing the overall specific energy consumption. We have screened some nanofiltration membranes for PFAS destruction.

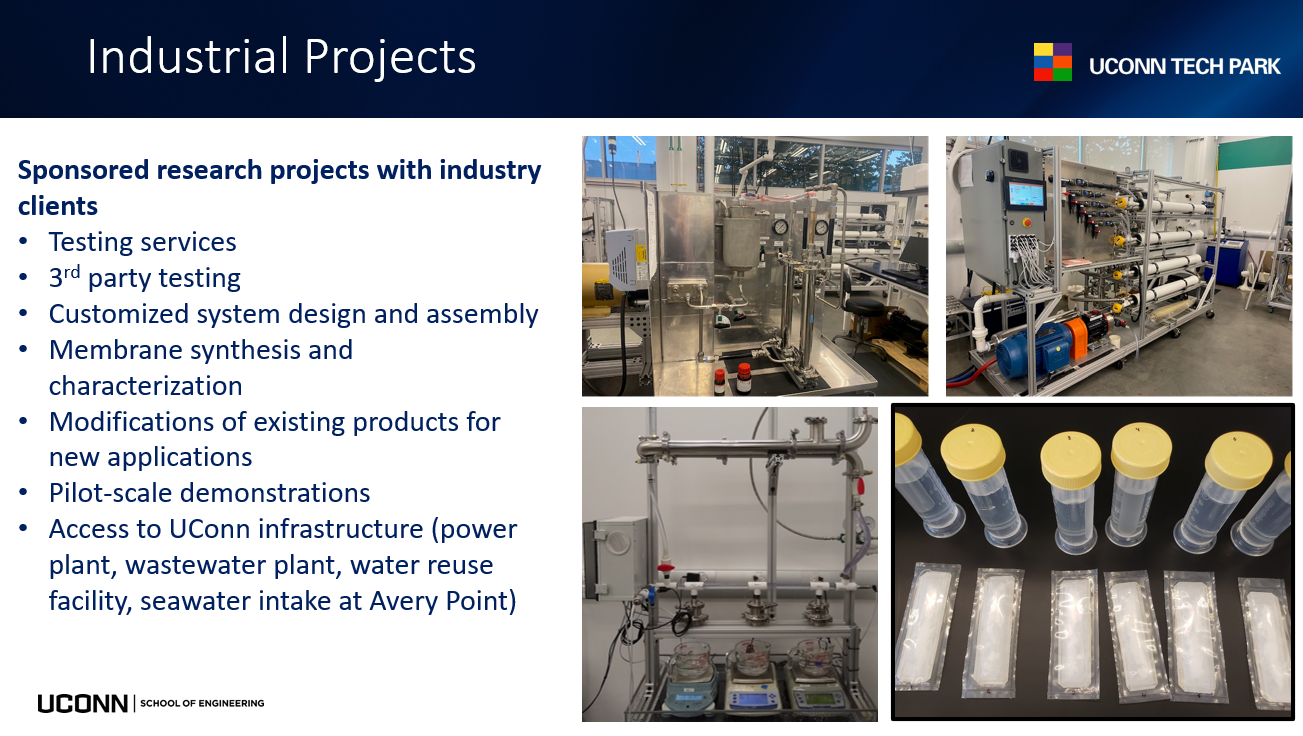

Industrial projects

We do a variety of industrial projects at CCAST. These can include testing services, water and gas treatment evaluation, membrane synthesis, testing system design and assembly, and membrane characterization. We offer a host of services that are supported by a full-time technical staff.